Allen's 383 Stroker Rebuild from Hell II!

Allen's 383 Stroker Rebuild from Hell II!

My 383 on the Blackstone dyno. Click for the Big Pic!

Updated: 12/19/99

All contents (C)1998-2002 Allen Woolley

Please Note: I am designing this to be more of a technical page, rather

than a glitzy brag page. Apologies if the page doesn't hook you as a result.

First things first: The engine made 485#/Ft of torque at 4200RPM and 488HP at

5900RPM.

First things first: The engine made 485#/Ft of torque at 4200RPM and 488HP at

5900RPM.

Click the photo to the left to see a clip of the dyno Torque and HP numbers in the stunning

Dot Matrix Elite font. The image to the right is a scan of the complete dyno data sheet.

This is particularly helpful to those folks that understand what a BSFC number means.

My goal of having my Vette be at least as powerful as my Camaro has been met, as my Z28 makes

~465HP at the flywheel (calculated from chassis dyno pulls).

The engine is the original numbers matching (you'll have to take my word on that, as the

numbers were lost when the deck was milled to 6.000") 29 year old 350C.I./350HP 11:1 L46,

but the block and original main bearing end caps are all that remains of the original

motor (NCRS Heresy, I'm sure :-).

The block has been align bored, the lifters bushed, cylinders overboard .030 and fitted

with a Lunati 3.75" stroker crank, 6" Eagle rods capped with SRP flat top pistons. Old

timers will immediately recognize this as the very traditional, no magic here, 383 cubic

inch long rod stroker motor recipe.

The block has been align bored, the lifters bushed, cylinders overboard .030 and fitted

with a Lunati 3.75" stroker crank, 6" Eagle rods capped with SRP flat top pistons. Old

timers will immediately recognize this as the very traditional, no magic here, 383 cubic

inch long rod stroker motor recipe.

Other tasty bits include Total Seal rings, Federal Mogul bearings, ARP fasteners, Fel-Pro

gaskets and the rest of the usual HiPo engine buildup suspects.

A port matched Victor Jr. aluminum intake manifold topped with a DaVinci modified Holly

750DP mechanical secondary carb (with a vacuum tap for my MSD vacuum advance distributor) is

bolted to a pair of ported World Products S/R Torquer cylinder heads.

Lunati 1.6:1 roller rockers are installed on the intake valves and 1.5:1 rockers are

installed on the exhaust valves. A CompCams roller cam

runs the valve train.

Why not aluminum heads?

Why not aluminum heads?

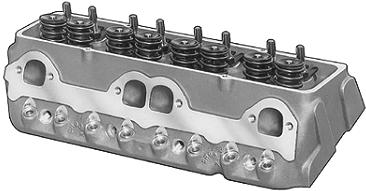

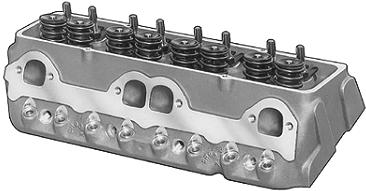

I want to explain why I chose iron S/R Torquer cylinder heads for this engine instead of

"modern" aluminum heads. I made this unconventional choice after talking to a *lot* of

knowledgeable folks about which heads to buy. I took that advice and information and combined

it with what I wanted the car to be like on the strip, road coarse and on the street.

My goal for this car is to build a hot street rod that can turn easy 12's at the quarter mile

track, run hard and reliably on the road course at Thunderhill, and be competitive at the AX

with a good driver behind the wheel (which I am most certainly not :-).

I also want the engine to maintain good street manners: reasonable idle, excellent throttle

response, good off idle cruising and some semblance of fuel efficiency (say 14MPG), in a quest

for the ultimate ET and MPH at the track.

The keys to achieving goals like these are to choose the heads and cam wisely. I chose the

heads, and Mike Blackstone chose the cam grind and DaVinci

carburetor to match the head flow characteristics after he ported them.

The World Products S/R Torquer cast iron heads are a small intake port volume design that

provides high charge velocity as opposed to the ultimate high flow volume. Keep in mind that

the S/R stands for "Stock Replacement". World Products designed this head as an affordable

replacement head that would out perform such original Chevy heads as the legendary

3927186 SBC "double hump" heads.

World was very successful in their design, and a stock S/R will perform much better than

even a mildly ported'186 Chevy head (of which I have 2 :-) will right out of the box.

Despite that, the S/R heads are not the ideal choice for track only use, but they do have two

excellent properties for a street rod compared to aluminum race heads: They are relatively

cheap at about $600 for a pair of bare castings, and they really do make outstanding low RPM

torque and power right out of the box if you buy them fully assembled for about $800.

However, if you build on the inherent robustness of the S/R design by performing the

usual porting operations:

1- Pocket porting/bowl blending

2- Porting the exhaust and intake runners

3- Gasket match the intake and exhaust ports

4- Trim back the intake valve guide casting

You will have a very nice performing race capable head that's almost up there with the big

dollar aluminum heads flow number wise, while maintaining street friendly high intake charge

velocity (read torque) all at a much lower cost.

You will have a very nice performing race capable head that's almost up there with the big

dollar aluminum heads flow number wise, while maintaining street friendly high intake charge

velocity (read torque) all at a much lower cost.

These qualities make ported S/R heads an excellent reasonable cost choice for a hot "real world"

street machine. To get more power, you have to go to a quality aluminum head such as the

Brodix Trac I, and also have it properly ported etc...

To buy a pair of aluminum heads and have them ported will run you at least $500 or more over

the cost of the ported S/R heads. Although you will see serious high RPM power with the aluminum head,

your low RPM torque may very well suffer significantly, particularly if you install a cam

large enough to take advantage of the wonderful high air flow the race heads are capable of

delivering.

My Blackstone ported S/R Torquer Flow Numbers are very interesting to compare to a

Blackstone ported Brodix Trac 1 head (which is a damn fine aluminum head by the way!)

pictured to the right.

Port volume: I=180 E=165.

|

Lift |

.100 |

.200 |

.300 |

.400 |

.500 |

.600 |

.700 |

|

Int |

81.2 |

151.3 |

213.7 |

252.8 |

257.7 |

265.8 |

269.8 |

|

Exh |

65.8 |

122.7 |

148.8 |

161.8 |

172.1 |

176.6 |

177.0 |

The 67cc combustion chambers yield a 92 octane friendly 9.9:1 static compression ratio with the 3.75" stroke Lunati crank and flat top SRP pistons installed in the engine.

Contrast these numbers with the Blackstone ported Brodix Trac 1 heads:

|

Lift |

.100 |

.200 |

.300 |

.400 |

.500 |

.600 |

.700 |

|

Int |

72.9 |

147.0 |

206.4 |

254.9 |

283.0 |

296.9 |

308.2 |

|

Exh |

59.0 |

118.5 |

172.4 |

212.4 |

227.9 |

230.9 |

232.1 |

This head would require an aggressive, high duration cam to take advantage of the huge flow numbers at the very high lifts. Note how the S/R head intake is flowing MORE than the Brodix head at low lifts. This is because of the S/R head's runner design building up velocity, which is the exact formula needed for good low RPM torque.

Mike stated the ported Trac 1 heads would make at least 40#/Ft and 80HP more than my ported

S/R heads. The question is: Where in the RPM band would that power be made?

The penalty for accessing the extra power the Brodix head is capable of would almost certainly

be a 6500+ RPM HP peak and comparatively poor < 3000 RPM torque. The engine would rock at

the 1/4 mile track though, which is why this is a true race head as opposed to a street head.

That's Nice, But So What?

The point of all this is that far too many guys go out and blow big bux on big bump sticks and

high dollar heads and all they end up with is an under performing, fuel hungry engine with bad

street manners and a whopper of a credit card bill.

Choosing a cam without having the flow numbers for your heads is a shooting in the dark

effort. You can only rely on other people's anecdotal experiences with the same model engine

and that's not necessarily going to be the ideal choice for your own engine or for your

intended vehicle use.

When designing an engine, you must first start with the head flow numbers.

Once those are known, you move onto the cam, which must take into account not just head flow

numbers, but also operating RPM, engine displacement, intake manifold flow and a host of

other things that are far, far over my head. An amateur such as myself must rely on either

his engine builder or the cam manufacturer's tech support staff.

When designing an engine, you must first start with the head flow numbers.

Once those are known, you move onto the cam, which must take into account not just head flow

numbers, but also operating RPM, engine displacement, intake manifold flow and a host of

other things that are far, far over my head. An amateur such as myself must rely on either

his engine builder or the cam manufacturer's tech support staff.

Trying to roll your own engine by throwing darts at the prettiest pictures in the Jegs or

Summit catalogs is highly unlikely to result in as powerful an engine as a methodical,

well researched approach will.

At the very least, the home engine builder should have his cylinder heads flow bench tested,

so that he can provide the proper information to the cam company's technical support guy,

so he can make an educated recommendation on what cam will work best in the engine.

When you call a cam company for assistance in choosing a cam, I'd think it'd be prudent

to have the following information at hand:

- Head flow numbers (offer to fax them to the guy!)

- Combustion chamber, intake runner and exhaust port volumes in cc

- Engine displacement

- Desired RPM range you want the peak torque and power in.

He will almost certainly ask you other questions like auto or manual transmission &ct...

Take notes on what the tech is telling you, that way, as you shop around, you will be

able to contrast the way different cam companies approach the problem.

I chose to neatly side-step the cam research by having my engine built by a pro. It's

significantly more expensive to go this route however (I saved for almost a year), and

is certainly beyond the financial reach of a lot of people out there, but...

Having your heads tested on a flow bench shouldn't run you more than an hour of shop time &

the information gleaned from it is well worth that modest investment if you want the best HP/$

spent on your engine.

Click to E-mail me

Back to Allen's Shark Page

First things first: The engine made 485#/Ft of torque at 4200RPM and 488HP at

5900RPM.

First things first: The engine made 485#/Ft of torque at 4200RPM and 488HP at

5900RPM. The block has been align bored, the lifters bushed, cylinders overboard .030 and fitted

with a Lunati 3.75" stroker crank, 6" Eagle rods capped with SRP flat top pistons. Old

timers will immediately recognize this as the very traditional, no magic here, 383 cubic

inch long rod stroker motor recipe.

The block has been align bored, the lifters bushed, cylinders overboard .030 and fitted

with a Lunati 3.75" stroker crank, 6" Eagle rods capped with SRP flat top pistons. Old

timers will immediately recognize this as the very traditional, no magic here, 383 cubic

inch long rod stroker motor recipe.

You will have a very nice performing race capable head that's almost up there with the big

dollar aluminum heads flow number wise, while maintaining street friendly high intake charge

velocity (read torque) all at a much lower cost.

You will have a very nice performing race capable head that's almost up there with the big

dollar aluminum heads flow number wise, while maintaining street friendly high intake charge

velocity (read torque) all at a much lower cost.

When designing an engine, you must first start with the head flow numbers.

Once those are known, you move onto the cam, which must take into account not just head flow

numbers, but also operating RPM, engine displacement, intake manifold flow and a host of

other things that are far, far over my head. An amateur such as myself must rely on either

his engine builder or the cam manufacturer's tech support staff.

When designing an engine, you must first start with the head flow numbers.

Once those are known, you move onto the cam, which must take into account not just head flow

numbers, but also operating RPM, engine displacement, intake manifold flow and a host of

other things that are far, far over my head. An amateur such as myself must rely on either

his engine builder or the cam manufacturer's tech support staff.